English

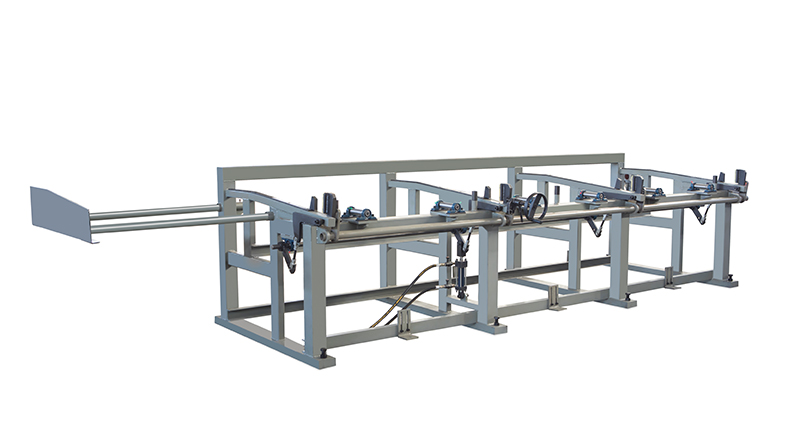

Feeding System

Applicable Models: 130 Machine and below. Driven by a servo motor, the high-precision ball screw utilizes high-strength linear guides and a floating swing method for automatic material feeding, effectively enhancing the precision and stability of the feeding process.

Integral Supporting Feeding Device

Applicable Models: 150 Machine and above. The feeding method is similar to the above, with the following advantages: Full-row support rollers: effectively prevent material sagging, which can lead to inaccurate cutting precision and material slippage damaging the machine. Rear auxiliary clamps: assist the main clamps in properly aligning the raw materials, resolving issues caused by the main clamps not properly securing the raw materials, which can result in skewed cutting.

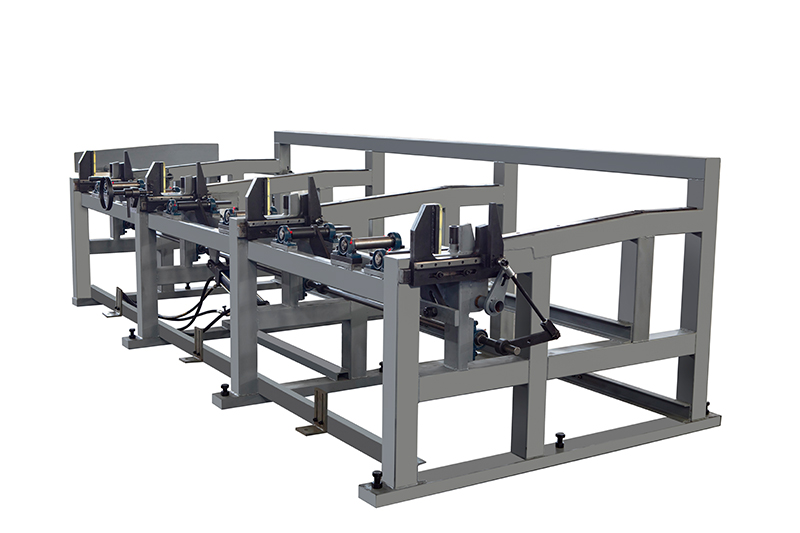

Automatic Feeding System

Applicable Models: 100 Machine and below. Used for arranging raw materials in rows for cutting, the system can be adjusted according to the outer diameter of the raw materials, and the length can be selected according to customer requirements. Paired with a control system, it fully meets the demand for one-time setup and mass production.

Buffer Automatic Feeding System

Applicable Models: 130 Machine and above. The feeding method is similar to the one on the left, with the following advantages: Buffer baffles: Hold the lifted raw materials in place, allowing them to roll down closely against the buffer baffle, resulting in no noise or impact. This effectively prevents the impact on the feeding system caused by the free rolling of lifted raw materials.