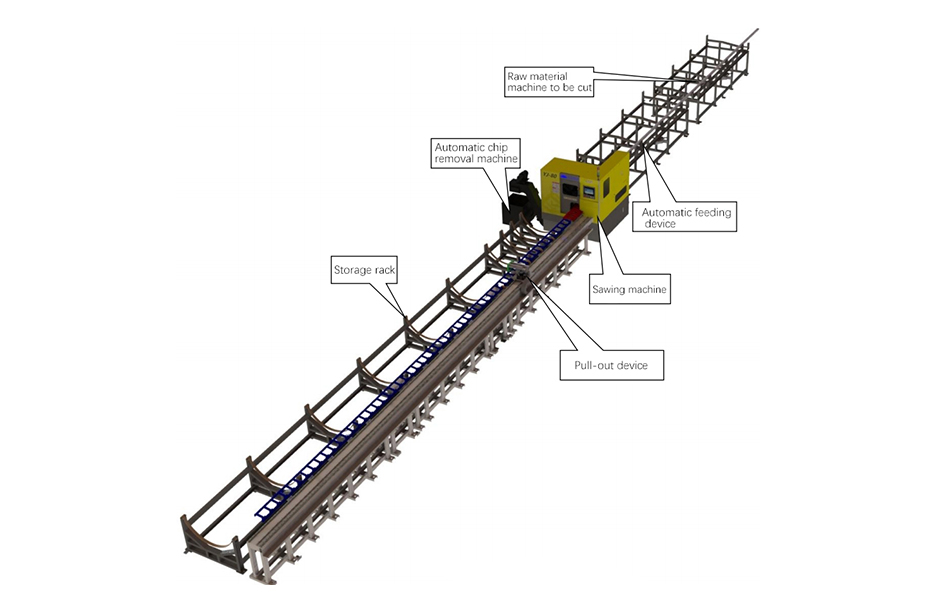

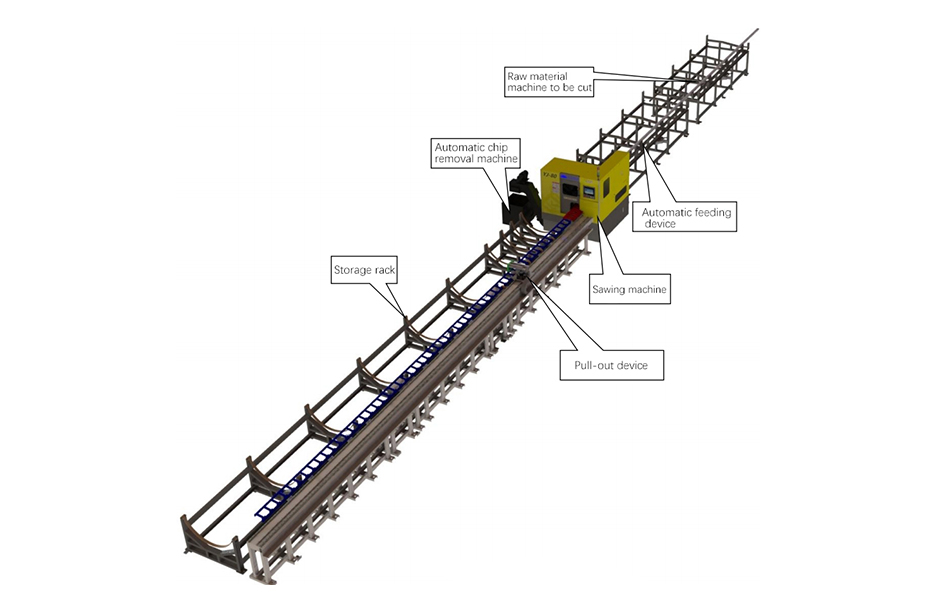

3-5 Meter Material Unloading Rack Automatic Production Line

3-5 Meter Material Unloading Rack Automatic Production Line

The puller device is primarily driven by a puller servo motor, which operates gears and racks to move the puller clamps along linear guides in a linear motion. Its main functions are: 1. To pull the finished products, after sawing, out of the sawing machine's main body and place them on the swivel roller assembly. 2. When the sawing length is between 3-5 meters, the feed clamp of the sawing machine's main body advances 1.6 meters in a single cycle, after which the discharge puller clamp directly grips the material and pulls it into position for sawing in one go, thereby enhancing production efficiency. When cutting lengths greater than 5 meters are required, the feed clamp of the sawing machine's main body and the discharge puller clamp work alternately to significantly reduce the feeding time.

The swivel roller assembly relies on the action of the flipping oil cylinder to rotate around its axis, tilting the finished workpieces on the swivel roller assembly and rolling them into the storage rack area. At other times, it remains in a horizontal state to support the workpieces. The discharge puller clamp pulls the sawed material out of the sawing machine's main body and can directly release the clamps to return for the next pull, without interfering with the action of the flipping roller assembly, thus saving discharge time.